Bead Blasted Surface Finish Specification

All aluminum alloys can be safely finished by wet barrel methods. Critical surfaces or features like holes can be masked to avoid any dimensional change.

China Glass Microspheres Surface Finishing 1 0 1 5mm Glass Bead For Blasting Abrasive China Abrasive Glass Beads

China Glass Microspheres Surface Finishing 1 0 1 5mm Glass Bead For Blasting Abrasive China Abrasive Glass Beads

Find high-quality picture Bead blasted surface finish specification

Walnut shells sand and glass beads are common.. Compared to other media glass beads are round and their mass is midway between lighter materials like plastic CO2 and organics. Specifying bead blasted finishes for stainless steel Bead blasted finishes for stainless steels are not covered in BS EN 10088-2 as a special finish type Table 6. The finer the blasting media the more corrosion resistant the surface performance.

Custom design is available. The front side will reflect the pattern and form a 3-dimentional like finish on the surface. The 80 PSI max line pressure is correct.

Any media can be used. Some additional standards and specifications that directly or indirectly affect surface finish requirements include. The surface finish achieved as in all blast operations basically depends on the kinetic energy of the particles which depends on their mass and speed and the hardness of the surface.

Bead blasting is essentially like a pressure washer that uses abrasive media instead of water. The finish is obtained by the use of finer grit belts or brushes which give a clean cut finish with a roughness of Ra05 microns maximum. Bead blasting adds a uniform matte or satin surface finish on a machined part removing the tool marks.

Finishes can be specified by considering the blast media the blast intensity and the coverage of the surface but should be agreed with specialist surface contractors. Fine glass bead blasting is commonly used on aluminum parts that need a dull or satin finish. Our local anodizer suggested a very fine bead blast aka peening.

Coarser glass bead is used to give a uniform rough finish while masking any imperfections in the substrate surface. Roughness for both No. Naturally steel will not have as much of a matte finish because it is harder but it will dull a polished surface.

Bead blasting adds a uniform matte or satin surface finish on a machined part removing the tool marks. Go with mil-9954-13 size 13 will give u a satin finish and surface roughness will be around 25 to 30 well i dont know your machine of blasting but if it is suction and u use staight long nozzle u can go with 40 psi max 6 off the part and angle 45 degrees note if the finish is not accepted u need brighter go to mil-9954-10 will help. Surface texture relies on the shape of the abrasive particle and the targets composition.

The impressive polished canopy of the Belgacom. Limitations imposed by workpiece size and shape are essentially the same as for steel and other metals. Bead blasting is the process most often used to achieve a surface finish that is both rough but consistent.

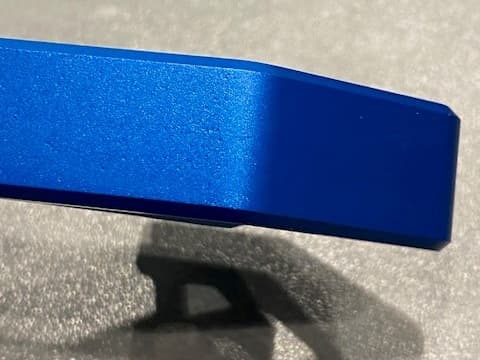

The Bead Blast Finish. This is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. While bead blasting usually leaves a softer peened shape on ductile materials.

A beadblast finish has some special characteristics that make it so popular and one of the most important of these is the reflectivity of a bead blasted metal surface how it reflects light. There are two gen- eral areas in which wet barrel finishing of alumi-. Our standard grit is 120.

Pick a media a pressure a distance from the part and then blast the surface. This matte finish can also be achieved using chemical acid etched bath as well. Specifying bead blasted finishes for stainless steel Bead blasted finishes for stainless steels are not covered in EN 10088-2as a special finish type Table 6.

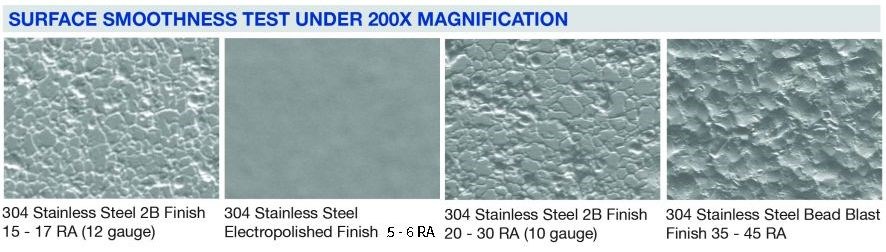

This smooth reflective surface makes it particularly suitable for most architectural applications especially exteriors where atmospheric performance is critical. Finishes can be specified by considering the blast media the blast intensity and the coverage of the surface but should be agreed with specialist surface contractors. When a spherical bead that is harder than the substrate impacts the surface at sufficient velocity it produces a round-bottomed dimple that behaves likes a tiny concave mirror when light.

The contacts shown were blasted with 006 beads. Bead-Blasted Finish to make a matte metallic finish. Bead Blasted The process of bead blasting utilizes bead mate - rial such as glass or ceramic beads to produce a non-directional textured surface with a soft satin appearance and low-reflectiv - ity.

Ultrafine glass bead blasting is an alternative to wet blasting. Bead blasted finish on stainless steel surface can best be described as frosted finish. Actual size of the beads can also make a difference in achieving the desired matte finish.

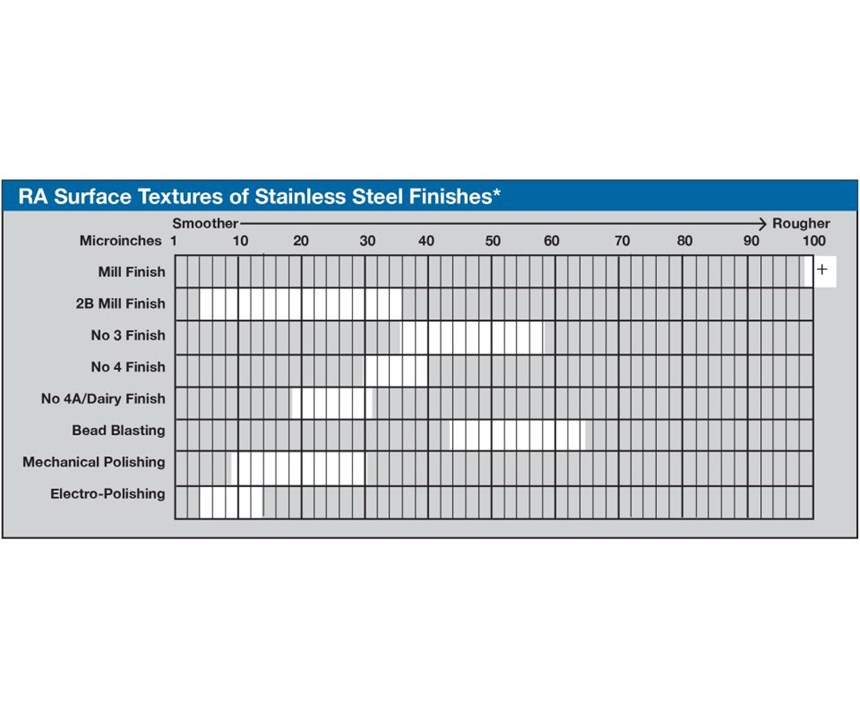

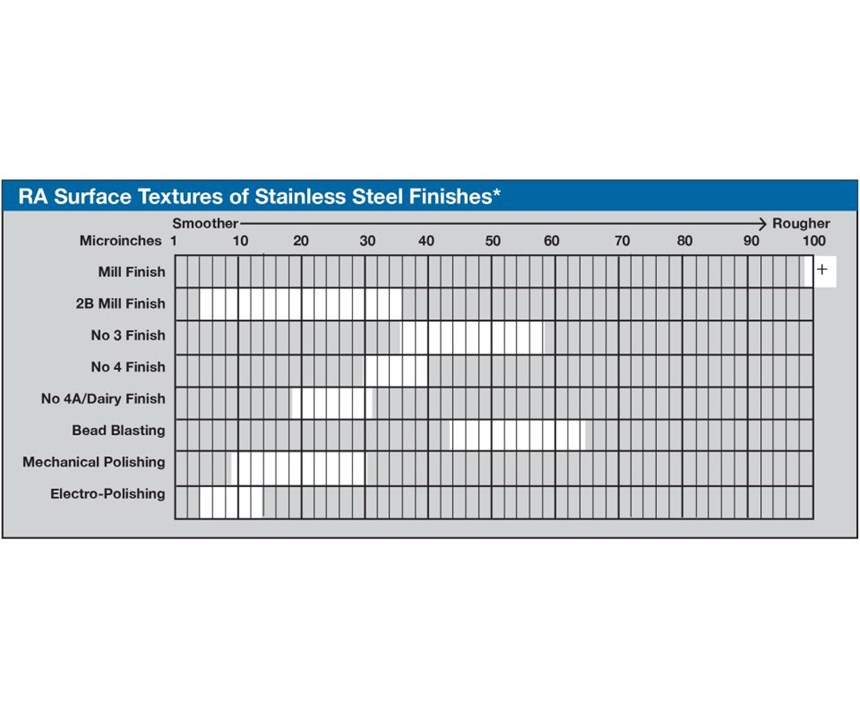

If you want to create a permanent strong and tight bond we recommend blasting with grit. Surface finish in fabrication Average Ra µm Bead blasted 100-600 Bored turned 040-600 Electropolished 010-080 It should be noted that the values in the table are for orientation only and that they vary between different producers and typical surface finish. Grit blasting tends to produce sharp gashes on ductile materials.

ASME B461-2002 - Surface Roughness Waviness and Lay ISO 4287 and 4288 - Geometrical Product Specifications GPS DIN ISO 1302 DIN 4768 - Comparison of Roughness. In bead blasting the part is bombarded with small glass beads using a pressurized air gun removing some material and smoothing the surface. Walnut shells sand and glass beads are common.

Need A Consistent And Repeatable Surface Finish

Need A Consistent And Repeatable Surface Finish

8 Lb Or 3 6 Kg 10 Glass Bead Blasting Abrasive Peening Media Extra Fine 170 Grit Or Commercial Spec No 10 For Blast Cabinets Or Sand Blasting Guns In Industrial Scientific

8 Lb Or 3 6 Kg 10 Glass Bead Blasting Abrasive Peening Media Extra Fine 170 Grit Or Commercial Spec No 10 For Blast Cabinets Or Sand Blasting Guns In Industrial Scientific

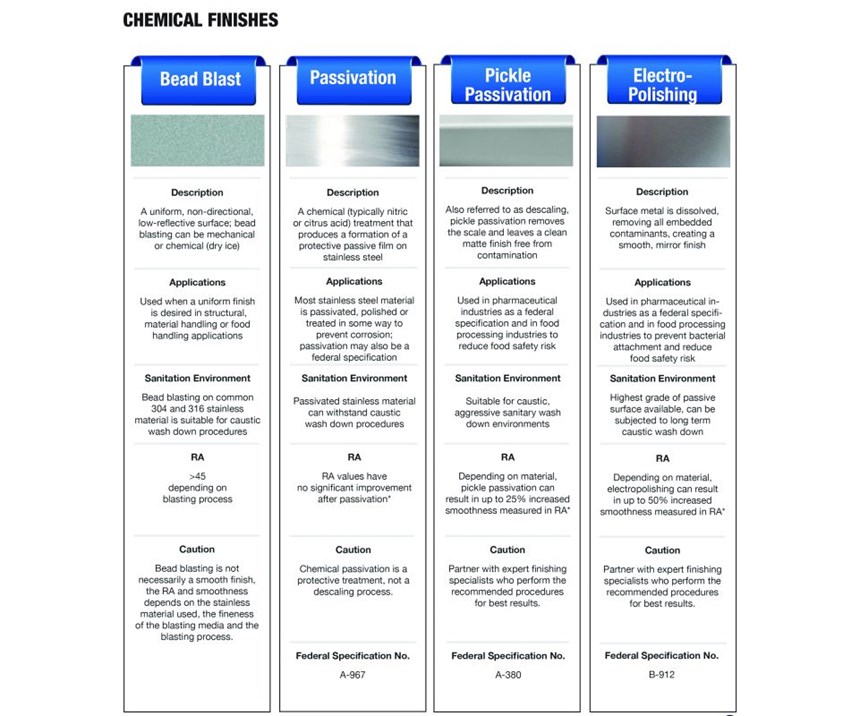

From Standards To Finishes Navigating The World Of Sanitary Design Process Expo 2021

From Standards To Finishes Navigating The World Of Sanitary Design Process Expo 2021

Mastering Sanitary Stainless Steel Finishes Finishing

Mastering Sanitary Stainless Steel Finishes Finishing

Bead Blasted Stainless Steel Sheet Color Stainless Steel Stainless Steel Texture Stainless Steel Sheet Designer Sheets

Bead Blasted Stainless Steel Sheet Color Stainless Steel Stainless Steel Texture Stainless Steel Sheet Designer Sheets

Need A Consistent And Repeatable Surface Finish

Need A Consistent And Repeatable Surface Finish

Wheelabratorgroup Media Files Wheelabrator Downloads W Plus Downloads Parts And Services Downloads Blast Media W2d Glassbead Media Eng 2016

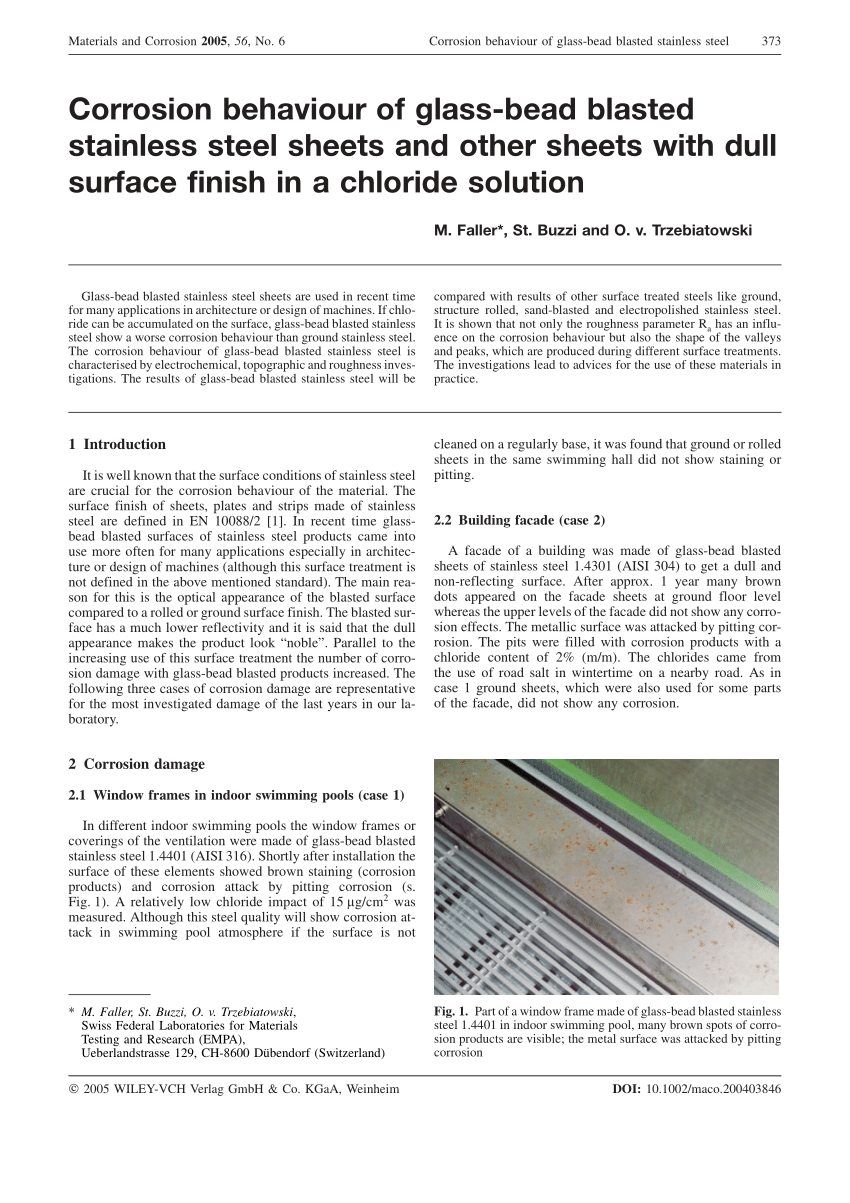

Corrosion Behaviour Of Glass Bead Blasted Stainless Steel Sheets And Other Sheets With Dull Surface Finish In A Chloride Solution

Corrosion Behaviour Of Glass Bead Blasted Stainless Steel Sheets And Other Sheets With Dull Surface Finish In A Chloride Solution

Leveraging Stainless Steel Finishes On Sanitary Equipment Pages 1 8 Flip Fliphtml5

Leveraging Stainless Steel Finishes On Sanitary Equipment Pages 1 8 Flip Fliphtml5

Mastering Sanitary Stainless Steel Finishes Finishing

Mastering Sanitary Stainless Steel Finishes Finishing

Mastering Sanitary Stainless Steel Finishes Finishing

Mastering Sanitary Stainless Steel Finishes Finishing

Surface Finish Bead Blasting Rapiddirect Manufacturing

Surface Finish Bead Blasting Rapiddirect Manufacturing

Cosmetic Finishing By Bead Blasting Guyson Corporation Of Usa

Cosmetic Finishing By Bead Blasting Guyson Corporation Of Usa

Grit Blast Microfinish Surface Roughness Comparator 32 1000 Microinch Engineering Books And

120 150 180 220 Grit Glass Bead Blasting Media

120 150 180 220 Grit Glass Bead Blasting Media

Surface Finishing Service Geomiq

Surface Finishing Service Geomiq

Surface Finish Bead Blasting Rapiddirect Manufacturing

Surface Finish Bead Blasting Rapiddirect Manufacturing

Corrosion Behaviour Of Glass Bead Blasted Stainless Steel Sheets And Other Sheets With Dull Surface Finish In A Chloride Solution

Corrosion Behaviour Of Glass Bead Blasted Stainless Steel Sheets And Other Sheets With Dull Surface Finish In A Chloride Solution

Need A Consistent And Repeatable Surface Finish

Need A Consistent And Repeatable Surface Finish

Bead Blasting Of Aluminum Specifications Q A Problems Soutions

Bead Blasting Of Aluminum Specifications Q A Problems Soutions

China Ceramic Bead Blasting Zirconia Beads B20 B400 For Metal Surface Finish China Ceramic Bead Blasting Zirconia Beads

China Ceramic Bead Blasting Zirconia Beads B20 B400 For Metal Surface Finish China Ceramic Bead Blasting Zirconia Beads

Glass Bead Blasting Jantz Canada

Glass Bead Blasting Jantz Canada

8 Lb Or 3 6 Kg 3 Glass Bead Blasting Abrasive Media Course 20 30 Grit Or Commercial Spec No 3 For Blast Cabinets Or Sand Blasting Guns In Industrial Scientific

8 Lb Or 3 6 Kg 3 Glass Bead Blasting Abrasive Media Course 20 30 Grit Or Commercial Spec No 3 For Blast Cabinets Or Sand Blasting Guns In Industrial Scientific

Source : pinterest.com